Polyether ether ketone, commonly known as PEEK, is one of the most advanced and versatile engineering materials. It can withstand demanding environments in ways that some traditional materials fall short.

If you would like to learn more about this important material so you can consider using it within your own components, this blog can help. Read on for a complete guide to PEEK, including its characteristics and its practical applications in modern engineering and industry.

What Is PEEK?

It is important to begin by defining what PEEK is. Developed in 1978, this high-performance thermoplastic polymer belongs to the polyaryletherketone family of plastics. Its highly ordered molecular structure and semi-crystalline nature allow it to perform consistently when subjected to extreme conditions. Today, a broad range of industries use PEEK plastic material, including the electronics, automotive, and medical sectors.

What Are Some of Its Benefits?

PEEK offers a range of properties that benefit its users. You can read about several of these advantages below and learn why you should apply PEEK to your own projects.

PEEK Is Very Tough

One quality that makes PEEK unique is its impressive toughness. PEEK maintains structural integrity under stress, and it doesn’t fracture when exposed to heavy impacts. This characteristic ensures that it performs effectively in dynamic applications subjected to repetitive motion and considerable force.

The toughness of PEEK translates into prolonged lifespans for components fabricated from this material. It is a reliable choice in environments where components are constantly in motion.

It Can Resist Extreme Temperatures

Another impressive feature of PEEK is its exceptional thermal stability, which allows it to withstand temperatures as high as 480 degrees Fahrenheit without significant loss of properties.

Whether exposed to prolonged heat or sudden thermal fluctuations, PEEK retains its shape, strength, and dimensional stability. High-temperature resistance ensures that products made from PEEK perform consistently under thermal stress.

PEEK Can Endure Many Acids

PEEK’s ability to resist many acids also sets it apart from other polymers. This plastic can withstand multiple bases, solvents, and other corrosive chemicals. Laboratories, oil fields, and process industries benefit from its robust performance against substances that would erode or degrade other materials.

This chemical resilience owes much to PEEK’s stable molecular architecture, which inhibits chemical interactions that could weaken it. As a result, the material lasts a long time and doesn’t require much maintenance, so heavy-duty industries can use PEEK to reduce maintenance costs and breakdowns.

It Has Insulating Properties

Electrical insulation is another defining feature of PEEK. The plastic prevents the transmission of electricity, presenting dielectric properties that withstand high voltages and currents without compromising performance. Apart from dielectric strength, PEEK maintains insulation across a broad temperature range and in hostile environments.

The Material Is Easy To Process

Engineers should also find the use of PEEK to be especially beneficial because it is easy to process. They can use methods such as injection molding, extrusion, compression molding, and even 3D printing.

Its high thermal stability ensures minimal degradation during these processes, allowing manufacturers to create intricate and precise components with excellent repeatability. This adaptability enables engineers and designers to meet complex application requirements while maintaining production efficiency.

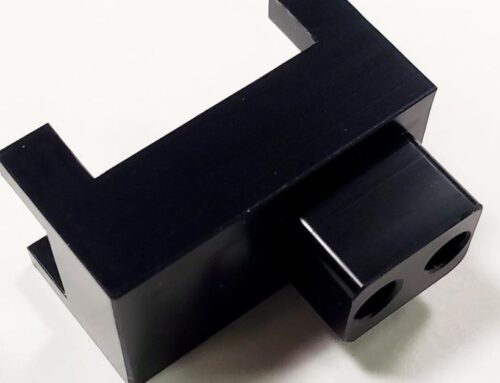

Additionally, PEEK’s ease of machining furthers its appeal for prototype development and custom solutions. Engineers can precision machine it into tight tolerances without compromising its mechanical integrity.

Furthermore, the plastic’s availability in various forms, including granules, rods, and sheets, simplifies integration into existing production lines. These characteristics collectively make PEEK an attractive material for versatile engineering and manufacturing projects.

What Are Several Uses of PEEK?

A guide to polyether ether ketone would not be complete without a look at several of its applications. Read on to learn more about a few key products that can incorporate this amazing polymer.

Bearings

PEEK’s toughness and low coefficient of friction make it an excellent material for manufacturing bearings. The polymer can endure rotational and linear movements with minimal wear and tear. Bearings fabricated from PEEK offer the advantage of reduced maintenance intervals compared to conventional materials, such as steel.

For instance, the aerospace and automotive industries employ PEEK bearings to reduce energy losses due to friction, improve reliability, and decrease downtime for repairs. Additionally, PEEK’s inherent lubricity makes it a viable option for dry-running applications.

Electrical Components

Electrical systems across industries require materials that resist conduction and thermal degradation while maintaining dimensional stability. As we have established, PEEK possesses both of those qualities, making it an ideal material for various electrical components, including insulators, connectors, and cable assemblies. Its robust performance under high-current loads ensures the safe and efficient operation of critical systems.

PEEK’s ability to maintain insulation in chemically aggressive and thermally challenging environments provides an added advantage. For example, it is frequently specified for use in marine and offshore equipment, where exposure to saltwater, extreme temperatures, and moisture calls for materials that combine insulation with corrosion resistance.

Medical Implants

PEEK has also enjoyed success in the medical field, particularly in the fabrication of implants. Its biocompatibility enables it to integrate with human tissue and cause no adverse reactions. Additionally, PEEK implants offer the dual advantages of chemical inertness and sterilization compatibility, allowing them to maintain a hygienic profile over the long term.

The plastic is increasingly replacing traditional materials like titanium in spinal implants due to its lighter weight and superior compatibility. Additional applications of PEEK in the medical field extend beyond implants to include surgical instruments and prosthetics. This versatility drives advancements in precision healthcare.

Engine Components

The exacting conditions within engines demand materials that remain strong, heat-resistant, and chemically stable during operation. PEEK meets these demands, making it indispensable in the automotive and aerospace sectors. Whether in piston components, gaskets, or valve seals, PEEK delivers outstanding performance under cycling pressure and heat.

For example, automotive manufacturers rely on PEEK to strike a balance between reducing component weight and enhancing durability. Its use supports energy efficiency by minimizing mass without sacrificing reliability. This feature resonates with industries continually seeking ways to improve operational efficiency and reduce costs.

Enjoy the Advantages of PEEK With Plastic Machining Inc.

Whether addressing the need for chemical, thermal, or mechanical resilience, PEEK offers exceptional versatility and performance. Its broad applications demonstrate its value as a material of choice in modern engineering.

Plastic Machining Inc. can help you enjoy this material’s advantages with our fabrication services. We can produce custom PEEK components that enable you to lower your costs without compromising quality. Get in touch today to get more information and discuss the needs of your project.

Leave A Comment