When engineers need high-quality materials for aerospace and semiconductor components, they often turn to Vespel®. This polyimide stands out in applications demanding exceptional thermal resistance, durability, and low friction.

However, understanding the different grades of Vespel® is key to selecting the appropriate material for your application. Read on for explanations of each one that will help you choose the right grade with the properties you need.

SP-1

SP-1 is the unfilled and pure form of Vespel® with outstanding physical and mechanical properties. It offers users excellent thermal stability, with the ability to handle extreme temperatures ranging from cryogenic conditions to up to 500 degrees Fahrenheit.

Vespel® SP-1 also features impressive electrical insulation properties, allowing for its use in electronic components. Its low outgassing and resistance to radiation further enhance its utility in aerospace and vacuum environments.

SP-21

Another example of the different grades of Vespel® is SP-21. By incorporating 15 percent graphite, this grade excels in dynamic applications involving sliding or rotational movement.

Engineers find this Vespel® material particularly effective for creating bearings, thrust washers, and seals. This grade’s wear resistance makes it a reliable choice for high-friction environments.

SP-22

Vespel® SP-22 builds upon the foundation of SP-2 by incorporating 40 percent graphite. This increased graphite content delivers even greater wear and friction resistance, making it a highly robust material for harsh operating conditions.

SP-22 is ideal for components requiring continuous movement under heavy loads or high temperatures. When companies use this material for bearings and wear strips, SP-22 consistently performs reliably.

SP-211

Another interesting variation in Vespel® is the SP-211 grade, which features 15 percent graphite and 10 percent polytetrafluoroethylene (PTFE). The addition of PTFE promotes self-lubricating capabilities.

This makes SP-211 perfect for applications where consistent lubrication might be challenging. This blend of additives ensures durability and performance under extreme conditions while optimizing operational efficiency.

SP-3

Last but not least, Vespel® SP-3 features a unique formulation that makes it useful in vacuum or dry environments. Incorporating 15 percent molybdenum disulfide enhances wear resistance and reduces friction even in situations where lubrication is impractical. The mix of low-friction characteristics and high thermal stability makes SP-3 a valued choice for applications ranging from spacecraft components to precision instruments.

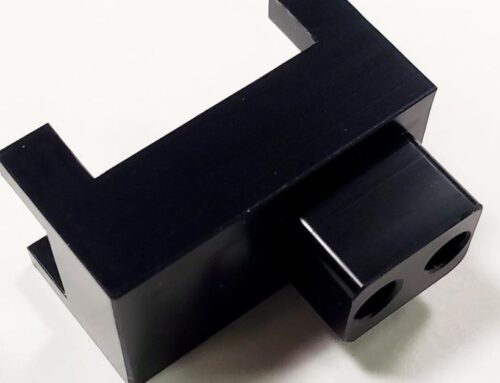

Get the Vespel® Grade You Need From Plastic Machining Inc.

After learning about the qualities of the various Vespel® grades, you can better determine which is uniquely suited for your specific challenge. One company that can supply you with components made from these different variations is Plastic Machining Inc. Our extensive experience in making Vespel® parts allows us to craft components that will rise to your challenges.